Premium Eyeshadow Cases

Struggling to keep your eyeshadow collection organized and intact? Eyeshadow cases transform your makeup routine with durable, stylish storage options.

Eyeshadow cases are essential for organizing and protecting eyeshadow pans. Typically crafted from plastic or metal, they come in various sizes to accommodate single or multiple shades. Many feature mirrors and applicators for convenience, along with secure closures to prevent spillage. Customizable designs and magnetic features allow easy replacement of pans. These cases often include compartments for organization and may be made from eco-friendly materials. Perfect for travel, they keep your makeup collection neat and accessible.

Features and Benefits of Eyeshadow Cases

Discover why our premium eyeshadow case packaging solutions are the perfect choice for your cosmetic brand, combining superior quality with customizable design options for multi-shade collections.

Key Features

Premium Materials

High-grade ABS, PC, and PMMA materials ensure durability and elegant appearance

Customizable Logo

Hot stamping, silk screen printing, UV coating, and laser engraving options available

Multiple Configurations

Various pan sizes from 2-shade to 12-shade configurations to meet different collection needs

Precision Manufacturing

Advanced injection molding technology ensures perfect pan fit and smooth hinge operation

Mirror Integration

Built-in high-quality mirrors with shatter-resistant coating for convenient application

Secure Closure System

Magnetic or snap-lock closure prevents accidental opening and protects eyeshadows

Benefits

Enhanced Brand Image

Premium packaging elevates your brand perception and creates luxury appeal for eyeshadow palettes

Cost-Effective Solution

Competitive wholesale pricing with flexible MOQ to suit your palette production needs

Product Protection

Superior protection prevents powder fallout and maintains eyeshadow integrity during transport

User-Friendly Experience

Ergonomic design and integrated mirror enhance makeup application convenience

Market Differentiation

Unique customization options help your eyeshadow collections stand out from competitors

Reliable Supply Chain

Consistent quality and timely delivery from our advanced manufacturing facility

Superior Quality

Premium materials and precision manufacturing ensure exceptional eyeshadow case quality

Custom Branding

Multiple customization options to perfectly match your eyeshadow palette brand identity

Wholesale Pricing

Competitive B2B pricing with flexible minimum order quantities for eyeshadow cases

Ready to elevate your eyeshadow packaging with our premium case solutions?

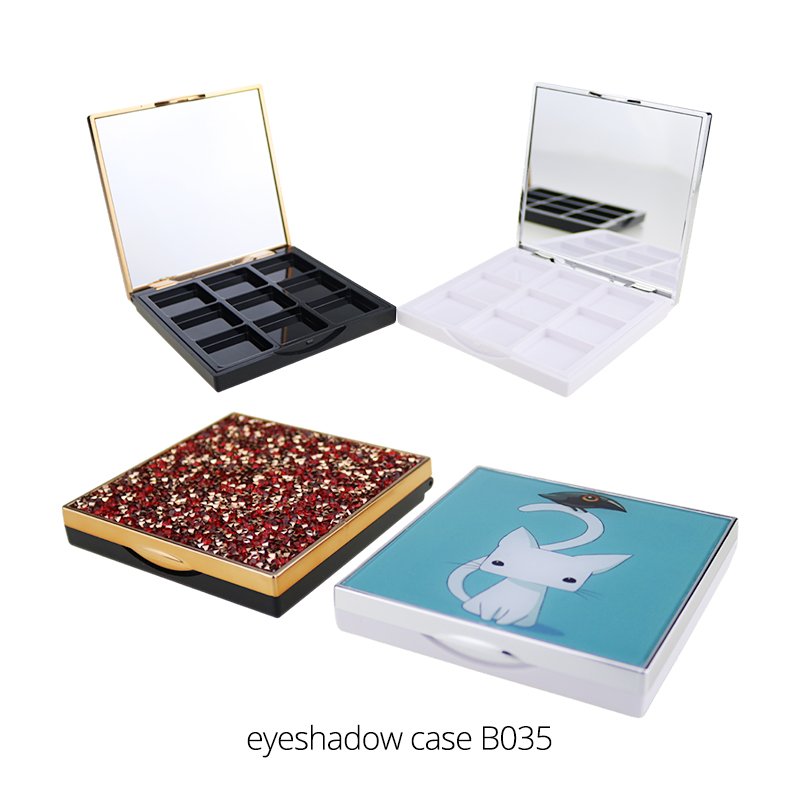

Our Eyeshadow Case Collection

Each case features precision mirror systems for flawless application, elegant aesthetics, and secure closure performance. Available in various pan configurations, sizes, and customization options for the ultimate eyeshadow experience.

Empty Eyeshadow Case Custom Eyeshadow Case Makeup Packaging Companies

Eyeshadow Palette Case Eyeshadow Case Manufacturers Custom Beauty Product Packaging

Custom Empty Eyeshadow Palette Case Eyeshadow Case Packaging Beauty Packaging Suppliers

Custom Eyeshadow Case Eyeshadow Case Manufacturers Custom Beauty Product Packaging

Empty Eyeshadow Palette Case Eyeshadow Case Wholesale Packaging For Beauty Products

Eyeshadow Case Manufacturers Custom Eyeshadow Palette Case Beauty Packaging Suppliers

Eyeshadow Case Wholesale China Empty Eyeshadow Palette Case Beauty Packaging Companies

Custom Empty Eyeshadow Palette Case Empty Eyeshadow Cases Custom Beauty Packaging

Custom Eyeshadow Palette Case China Empty Eyeshadow Case Beauty Products Packaging

Why Choose JCCosmopack for Cosmetic Eyeshadow Cases

With over a decade of expertise and 10 state-of-the-art injection molding machines, we deliver superior quality eyeshadow case packaging solutions to brands worldwide.

Superior Quality Assurance

Every eyeshadow case undergoes rigorous quality control processes using advanced injection molding technology, ensuring consistent excellence and secure powder protection for your brand.

Customized Logo Solutions

Transform your vision into reality with our comprehensive logo customization services, allowing your brand identity to shine through every eyeshadow case design.

Advanced Manufacturing

Our 10 precision injection molding machines operate with cutting-edge technology, delivering high-volume production capabilities while maintaining exceptional quality standards.

Global Market Expertise

With proven success across Southeast Asia, Middle East, and South America, we understand diverse market requirements and international quality standards.

B2B Wholesale Focus

Dedicated exclusively to B2B wholesale operations, we offer competitive pricing, flexible MOQs, and streamlined processes tailored for business partnerships.

Comprehensive Support

From initial design consultation to final delivery, our experienced team provides end-to-end support, ensuring seamless collaboration throughout your project lifecycle.

Trusted by Beauty Brands Worldwide

Our eyeshadow cases have been the choice of leading cosmetic brands, packaging middlemen, and finished product factories across multiple continents. With JCCosmopacks, you're not just getting a supplier – you're gaining a strategic partner committed to your success.

Ready to Elevate Your Brand?

Contact Leo Chen today to discuss your cosmetic eyeshadow case requirements and discover how JCCosmopacks can bring your vision to life with superior quality and customization.

Premium Customization Processes

Transform your cosmetic packaging with our advanced finishing techniques. Each process delivers unique aesthetics and enhanced functionality for your brand.

Electroplating

Premium metallic finish with chrome, gold, or silver coating for luxury appearance and corrosion resistance.

Screen Printing

High-quality ink application for vibrant colors, logos, and detailed graphics with excellent durability.

UV Coating

Glossy or matte protective finish with instant curing for enhanced scratch resistance and visual appeal.

Spray Painting

Uniform color coating with various finishes including metallic, pearl, and solid colors for brand customization.

Vacuum Metallizing

Ultra-thin metallic layer deposition for mirror-like finish with exceptional adhesion and uniformity.

Rubber Paint

Soft-touch coating providing premium tactile experience with anti-slip properties and elegant matte finish.

3D Printing

Advanced additive manufacturing for complex geometries, prototyping, and small-batch customization.

Water Transfer Printing

Hydrographic printing for complex patterns, textures, and designs on curved surfaces with seamless coverage.

Hot Stamping

Heat-activated foil transfer for metallic logos, text, and decorative elements with precise detail and durability.

Ready to Customize Your Packaging?

Our expert team combines multiple processes to create unique, high-quality cosmetic packaging that elevates your brand presence.

Frequently Asked Questions

Everything you need to know about our eyeshadow case manufacturing and customization services

What's your minimum order quantity for eyeshadow cases?

Our MOQ varies by case type and customization level, typically ranging from 8,000 to 12,000 pieces. Standard cases have lower MOQs, while fully custom multi-pan designs require higher quantities for cost efficiency.

Can you create custom pan configurations for eyeshadow palettes?

Absolutely! We offer flexible pan layouts from 4-pan to 24-pan configurations with various shapes - round, square, rectangular. Custom inserts and dividers can be designed to match your product specifications.

What's the typical lead time for custom eyeshadow cases?

Standard customization (color, logo): 18-25 days. New mold development: 30-35 days. Rush orders available with 10-12 day express service for existing designs.

Do you provide samples with mirrors and applicators?

Yes, we provide complete samples including high-quality mirrors and foam applicators. Custom samples with your specific mirror size and applicator preferences are available for evaluation.

What closure mechanisms do you offer for eyeshadow cases?

We offer various closure options including magnetic closures, snap-fit mechanisms, and premium hinged designs. All closures are tested for durability and smooth operation to ensure premium user experience.

Can you accommodate both pressed powder and cream eyeshadow formats?

Yes, our eyeshadow cases are designed to accommodate various formulations. We can customize pan depths and materials to suit pressed powders, cream shadows, or hybrid formats based on your product requirements.

What finishing options are available for eyeshadow cases?

We offer premium finishings including soft-touch coating, metallic plating, holographic effects, embossing, hot stamping, and UV spot coating to create distinctive luxury packaging for your brand.

Do you offer refillable eyeshadow case solutions?

Yes, we specialize in sustainable refillable designs with magnetic pan systems that allow easy replacement. These eco-friendly solutions support circular beauty initiatives while maintaining premium aesthetics.